If the bar in question is an uncoated #6 bottom bar, with a yield strength of 60 ksi in normal weight concrete (f ‘ c = 4,000 psi), ACI 318 section 12.2.2 would yield a basic development length (and Class A lap splice length) of 29 inches. We can only hope!)Ĭonsider our contractor’s dilemma. (As a side note, one wonders if ACI 318 Appendix D might someday offer a similarly simple but conservative approach. The positive of this is a simple design the negative is a conservative design. Hence, simply substituting this value offers a conservative result that is reflected in the relationships of ACI 318 section 12.2.2. For this equation, ACI recognizes that, in virtually all cases, the ( c b+ K tr)/ d b value is at least 1.5. As such, the results of this calculation offer a less conservative result for development length, but with increased complexity of the calculation itself. While this equation has considerable similarity to the equations of ACI 318 section 12.2.2, it also includes a distinct difference: the ( c b+K tr)/ d b term offers the potential for explicitly including the benefits of other factors that contribute to development length, specifically bar cover/spacing ( c b) and transverse reinforcement index ( K tr). While the provisions of ACI 318 section 12.2.3 are secondary to the aforementioned section 12.2.2, fundamental research led to the development of the following empirical relationship (ACI 318, Equation 12-1): Is there another alternative?ĪCI 318 allows for a rational and simple solution. He would be happy with option D initially, but upon further consideration may wonder how much money is being wasted on the project due to your conservative design.

Do you:Ī) instruct him to cancel his concrete pour until the problem can be fixed?ī) allow him to continue as planned, but add more bars (excess reinforcement) at the lap splice that will effectively lap with each of the bars in question?Ĭ) tell him that he can proceed if he splices the bars with mechanical couplers?ĭ) allow him to proceed without changes, since your design was conservative?Ĭertainly any of these options might be pursued, but the first three are not likely to be favored by the contractor and may be injurious to the good working relationship that you have been striving to foster with him for many years. Final inspection of rebar placement has occurred and the inspector has found, due to some unknown error, that the lap splices on a particular size bar in the bottom a mat foundation are short by 6 inches. Perhaps you have been a party to the following scenario, or something akin to it: You get a call from a contractor planning to place a large volume of concrete the next day. However, the simplicity introduced within this discussion does come with a price – a conservative design. This might even be the basis of standard lap splice length schedules used by your office. With this as a basis, the development of standard schedules, details and embedment length versus bar diameter relationships become fairly trivial. If we further assume that the material properties (f y and f ‘ c) are constant, the only differentiators become the fraction coefficient (which is basically the size factor) and whether more than 12 inches of fresh concrete is cast below the bar (Ψ t).

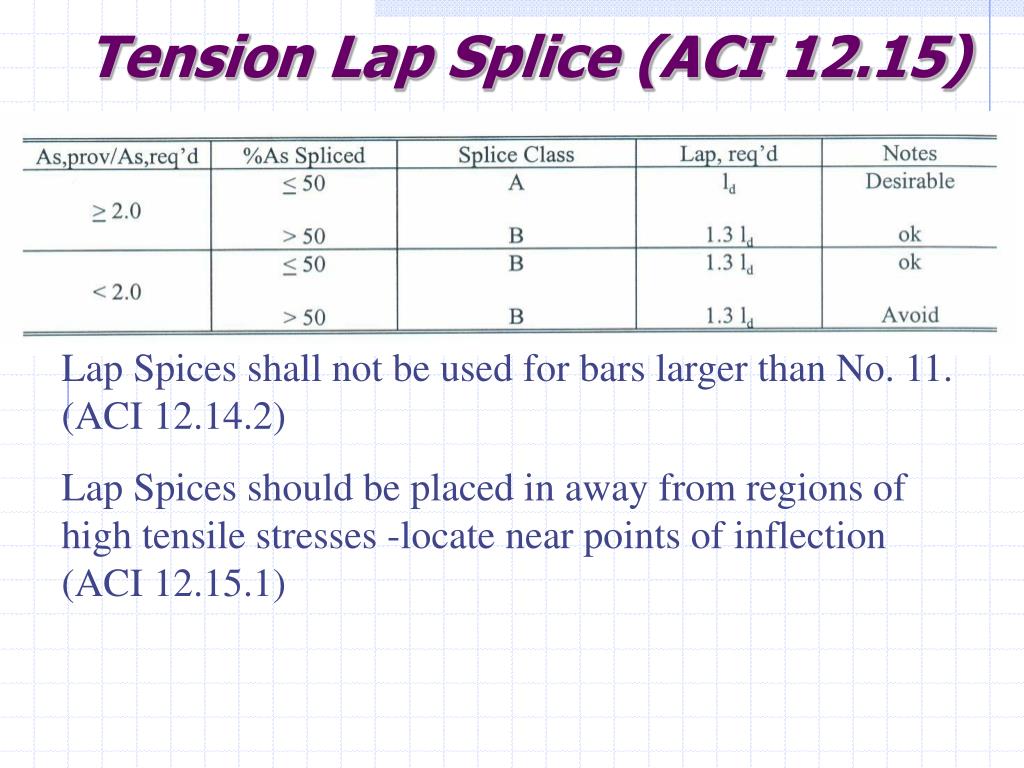

From this, we can surmise that basic development lengths ( l d) follow the form: For most of us, the provisions for development length and lap splices of reinforcing steel are taken from ACI 318-11, Table 12.2.2.

0 kommentar(er)

0 kommentar(er)